This is the right way to add sodium hypochlorite, which kills other disinfection processes!

This is the right way to add sodium hypochlorite, which kills other disinfection processes!

If you say which kind of pharmaceutical disinfection is used in sewage treatment, chlorine disinfectants must be on the list; if you say which of these chlorine disinfectants is the best to use, it must be considered sodium hypochlorite.

Nowadays, many water plants are disinfected mainly with liquid chlorine, which has a strong germicidal capacity, low price and easy to add, so we all use it smoothly. But the disadvantages are also quite obvious.

✦ One is the problem of chlorine-containing disinfection by-products.

✦ Two, problems that arise in actual use, such as chlorine not being dosed at low temperatures.

✦ Third, there are more significant safety hazards, such as the difficulty of liquid chlorine management, the risk of the transportation process, liquid chlorine explosion is not a joke.

Sodium hypochlorite is different, although the principle of disinfection is similar to that of chlorine gas, which is formed by hydrolysis of hypochlorite. The difference is that chlorine hydrolysis produces carcinogenic chlorinated organic compounds in water, while sodium hypochlorite disinfection is relatively safe, in other words, the water quality disinfected with sodium hypochlorite is better than that disinfected with liquid chlorine.

1.Sodium hypochlorite disinfection process

Disinfection mechanism of sodium hypochlorite

Sodium hypochlorite is a highly effective chlorine-containing disinfectant. Its disinfection action mainly includes the action of hypochlorous acid, the action of nascent oxygen and the action of chlorination. The oxidation of hypochlorite is the main disinfection mechanism of chlorine-containing disinfectants.

Chlorinated disinfectants form hypochlorous acid in water, which acts on bacterial proteins. Hypochlorous acid not only interacts with the cell wall, but also has a small molecular size and is uncharged, so it can invade the cell and oxidize or destroy its phosphate dehydrogenase causing cell death.

At present, the use of sodium hypochlorite disinfection can be divided into two forms, one is the application of sodium hypochlorite generator online generation of sodium hypochlorite solution; the second is the use of sodium hypochlorite finished solution. Regardless of the method of dosing, it is widely favored by water divisions around the world because of its high safety.

Superiority of sodium hypochlorite disinfection

High efficiency: disinfection effect is not much different from liquid chlorine, and has the ability of continuous disinfection.

Safety: Non-toxic and harmless to the environment, no danger of leakage or explosion.

Other effects of sodium hypochlorite disinfection

- Removal of iron and magnesium by oxidation.

- Removal of manganese by oxidation in conjunction with a filter tank.

- Conversion of H2S to H2SO4, effective removal of hydrogen sulfide odor in water (especially from groundwater sources).

- Remove ammonia nitrogen from wastewater by oxidation.

2.Sodium hypochlorite detection method

Indirect iodometric determination

Since sodium hypochlorite has strong oxidizing property, a certain amount of sample is oxidized with potassium iodide in acidic medium, and a considerable amount of iodine is released, then sodium thiosulfate standard solution is used to titrate iodine, and then the content of effective chlorine in sodium hypochlorite is calculated according to the consumption of sodium thiosulfate standard solution. This method is simple and has high sensitivity and accuracy.

3.Comparison of Disinfection Processes

Advantages and disadvantages of the application of liquid chlorine disinfection technology

Liquid chlorine disinfection technology has a strong inactivation capacity for bacteria, has a continuous disinfection effect, does not require the use of large equipment, is relatively simple to dose, and has low investment and operating costs.

However, if the water contains high levels of organic nitrogen, the chlorination reaction is extremely complex, generating various organic chlorides, and it takes a long time for the residual chlorine value to stabilize. Chlorine gas is highly toxic and poses a major safety hazard when used.

Advantages and disadvantages of chloramine disinfection technology

Chloramine disinfection technology can reduce the amount of trihalomethanes generated compared to chlorine disinfection, reduce chlorophenol taste, and increase the duration of residual chlorine in the water supply network and inhibit the production of bacteria in the network.

Compared to other disinfection technologies, the contact time of chloramine with water is not less than 2 hours, which is 4 times longer than other disinfection technologies, and requires appropriate dosing and modulation equipment.

Advantages and disadvantages of sodium hypochlorite disinfection technology

Sodium hypochlorite disinfection technology has strong sterilization ability, long duration and simple operation compared to other disinfection methods.

However, sodium hypochlorite cannot be stored for a long period of time, usually about 10 days, and there is another way to obtain sodium hypochlorite, which is prepared on site, and the size of the equipment used to make it is small.

Advantages and disadvantages of the application of chlorine dioxide disinfection technology

Chlorine dioxide disinfection technology is little affected by water temperature and pH, has a contact reaction time of about 30 minutes with water, has a long continuous disinfection time in the pipe network, can effectively kill viruses and two insects, has a strong oxidizing effect, can deodorize, decolorize, oxidize manganese, iron and other substances.

The dosage of hydrochloric acid and transportation approval are strict, and the chlorine dioxide generated is easy to decompose, so it needs to be made and used now. And chlorine dioxide is easy to explode (10% air content, 30% solution), for ventilation, management requirements are high.

A comparison of conventional disinfectants shows that chlorine, chloramine and chlorine dioxide have the potential to react with organic and inorganic compounds in the water to produce toxic or “tri-causal” by-products, and have greater safety risks and operational management difficulties.

Sodium hypochlorite disinfection has a wide range of sterilization effect, its sterilization ability is strong, there is a continuous sterilization effect and certain algae, deodorization, deodorization ability, the effect is comparable to chlorine. As a disinfectant, it is safe to use and there are no safety hazards, and the raw material for its preparation is table salt, which is convenient to purchase.

4.Comparison of sodium hypochlorite dosing processes

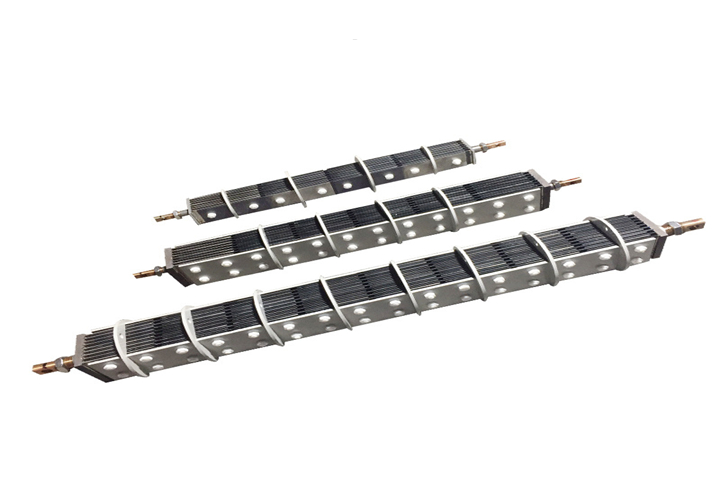

At present, the mainstream sodium hypochlorite dosing systems are mainly divided into “dosing with purchased sodium hypochlorite solution” and “dosing with on-site preparation by sodium hypochlorite generator”, and the comparison of these two dosing systems is shown below.

From the above comparison, it can be seen that the disinfection effect and the cost per ton of water treated are comparable between the two dosing methods.

Therefore, for places with sufficient supply of finished chemicals (more than three companies meet the supply requirements), it is recommended to use purchased finished sodium hypochlorite solution for disinfection, which has relatively low operation and maintenance costs, short equipment ordering and construction cycles, and no special requirements for operation and maintenance.

For small-scale water purification plants, especially in areas with inconvenient sources of goods and transportation, it is recommended to use sodium hypochlorite generators for on-site preparation and injection to avoid the hidden problem of poor disinfection caused by long storage decay of pharmaceuticals.

5 Use of sodium hypochlorite also need to pay attention to.

In summary, with the improvement of sewage safety treatment, from the disinfection by-products, safety supervision, disinfection effect and other aspects of comprehensive consideration, sodium hypochlorite instead of liquid chlorine have become a trend. Of course, there are several points that need to be noted.

1, for the characteristics of raw water quality, clear and reasonable chlorine dosing point, according to the number of dosing points and distribution, reasonable selection of chlorination metering pump parameters and size, as far as possible to use the same parameters of the equipment, reduce the number of spare pumps, easy to maintain later.

2, sodium hypochlorite dosing pipeline and storage tanks are easy to crystallize, the design should consider high-pressure water flushing system, and it is best to set up a backup dosing pipe to ensure stable operation.

3、For the convenience of observation and maintenance, sodium hypochlorite dosing pipeline should be laid in the pipe trench.

4, Sodium hypochlorite waste liquid should have a special collection pool, which should be treated by relevant units or manufacturers and should not be discharged at will.

It is foreseeable that the prospect of sodium hypochlorite as the best substitute for wastewater disinfectant is still very promising in China, where more and more attention is paid to the safety of wastewater treatment.