Chlorine Dioxide Titanium Anode

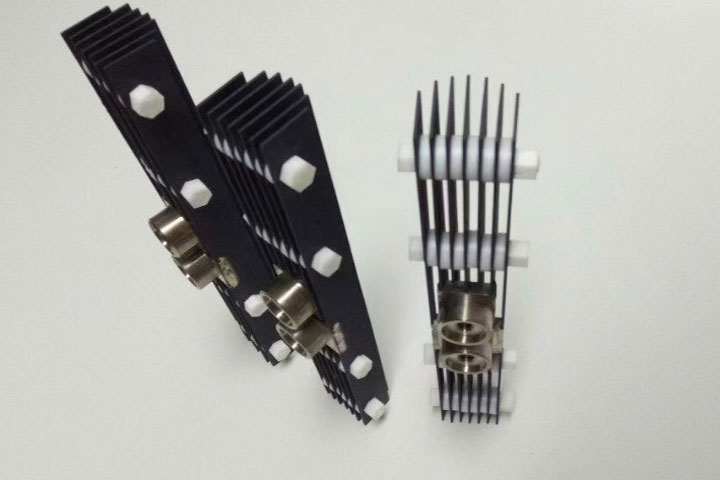

Substrate: Titanium Grade 1 mesh

Coating: Ru-Ir-X

The working principle of chlorine dioxide generator.

A sodium salt solution containing chlorine is added to the anode plate of the electrolyzer, and water is added to the cathode chamber, which can be electrolyzed by turning on the power. At the same time, the anode chamber produces a variety of pure disinfection gas containing ClO2, Cl2, O3, H2O2, etc., and then through the water injector, the highly efficient mixed disinfection gas is fully mixed with the water to be treated to achieve the purpose of disinfection treatment.

Odevs provides a titanium anode for chlorine dioxide generators (quadruple, quintuple, new formula coating), which has more superior electrolysis effect than before and the energy consumption is reduced by 10-20%. The advantages of titanium anode for chlorine dioxide generator titanium electrodes (quadruple, quintuple, new formula coating) are mainly reflected in.

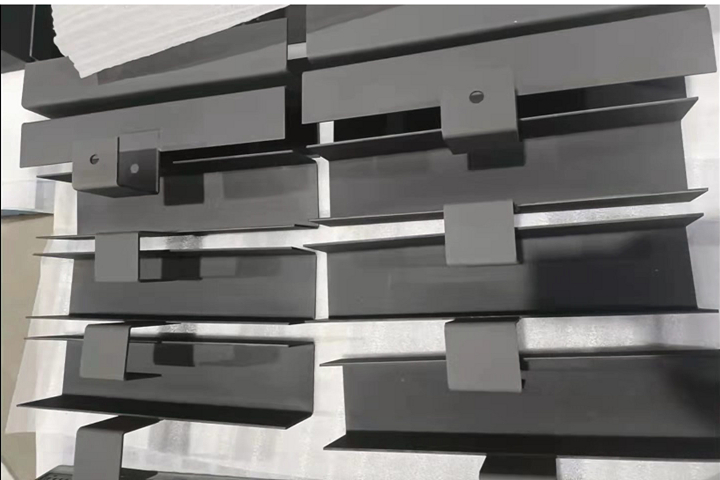

- stable size of titanium anode, the distance between electrodes does not change during electrolysis, which can ensure the electrolysis operation under the condition of stable tank voltage.

- low working voltage, low power consumption, DC power consumption can be reduced by 10-20%. 3.

- Titanium anode has a long working life and strong corrosion resistance.

- It can overcome the dissolution problem of graphite anode and lead anode and avoid the pollution of electrolyte and cathode products.

- High current density, small over-potential, and high catalytic activity of electrode, which can effectively catch high production efficiency.

- After long-term practice and experiments, it is proved that the new coated titanium anode titanium electrode of ODEVS has high product quality, high purity and concentration of chlorine dioxide, and can save energy consumption.

- It can avoid the short circuit problem after the deformation of the lead anode and improve the current efficiency.

Titanium anode for electrolysis of chlorine dioxide has the following advantages.

- The use of the titanium anode electrolysis method to produce chlorine dioxide also generates O3, CL2, H2O2, and other strong oxidizing and widespread sterilization abilities, the disinfection effect is far better than the chemical method.

- Low cost of disinfection by electrolysis

- Good safety, production materials transportation, storage, and operation safety. The chemical method of chlorine dioxide production requires chlorine gas, which is very inconvenient to transport and store, and more importantly, there are great safety hazards.

- The source of raw materials is easy: electrolysis method to produce chlorine dioxide, the principle is to use titanium anode electrolysis of salt water, compared with chlorine gas, salt water is more convenient and safer operation. For chlorine dioxide generators, generally use a ruthenium-iridium coated plate, and mesh titanium anode, our company provides shaped parts custom

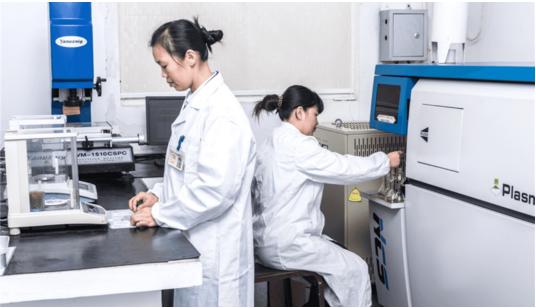

Quality checks:

Accelerated Life Test, Coating Thickness Test, Coating composition test, Conduct electricity conductivity testing,

Surface roughness test, Helium Leak Detection Test, Contact Resistance Test, Electrochemical Performance Test, and other tests.

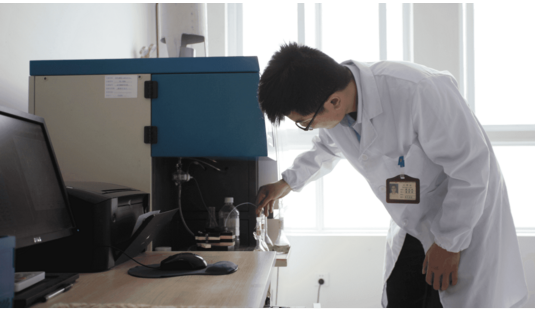

JOINTING R&D

Improving current efficiency and prolonging service life are the core technical indicators of DSA titanium electrodes. Different industries have different requirements for the performance of titanium electrodes. Even if the same industry uses the same system of electrocatalytic coatings for different electrolytes, it may not be possible. Bring the ideal use effect. Based on years of accumulated R&D and production experience and a high-level technical team, the company can tailor a coating system that meets its own production environment for target customers to meet the differentiated needs of different industries or different customers in the same industry.

Development of electrode materials for high chlorine evolution efficiency and long life. Development of electrode materials for high acidity and long-life oxygen evolution. Development of new electrode materials for mixed acid systems.

Development of high-oxygen ultra-base metal electrode materials Development of electrode materials in special fields