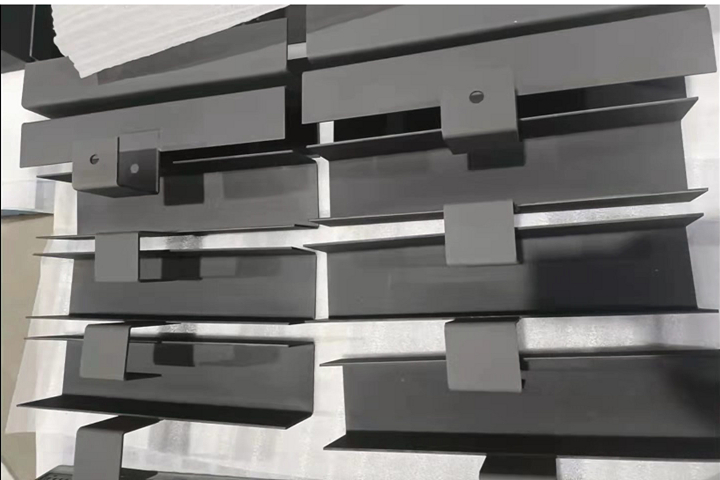

Titanium electrodes for galvanizing and tin plating of steel sheets

Substrate: Titanium Grade 1 Sheet

Coating: Iridium-tantalum/ruthenium-iridium

Current density: 600-1500A/m²

In electroplating applications, the desired plating metal is dissolved in the electrolyte, the plated metal substrate is used as the negative electrode, and the anode is used as the positive electrode, forming a complete current transfer cycle. The chemical reaction that occurs in the electroplating bath in conjunction with plating is the precipitation of oxygen on the surface of the anode.

Reference parameters.

- Substrate material: TA1

- Coating: Iridium-tantalum/ruthenium-iridium

- Current density: 600-1500A/m²

- Process: hand-painted, sintering, etc.

- Life: design a life of 6 months -5 years. According to the actual working conditions of customers to choose

- shape plate, mesh, tube, etc., can be processed to customize shaped parts

Reaction mechanism.

Anodic reaction (on the surface of the anode): 2H2O→O2↑+4H++4e

The main cathodic reaction (on the surface of steel plate): Zn2+2e→Zn/Sn2++2e→Sn

Cathode surface reaction: 2H2O+4e→H2↑+2OH-

Advantages.

1. low tank voltage and low energy consumption.

2. small rate of electrode loss and dimensional stability

3. good corrosion resistance of the electrode, less anode integration into the transition solution, keeping the transition solution clean, and making the performance of the plating more reliable.

4. new material and structure of titanium anode, which greatly reduces its weight and facilitates daily operation.

5. Long service life and reusable substrate, saving cost.

6. Oxygen separation overpotential is about 0.5V lower than that of lead alloy insoluble anode, resulting in lower tank voltage and lower energy consumption.

Applications.

Zinc plating, including steel plate galvanizing; precious metal plating (including gold plating, silver plating, palladium plating, etc.); hard chromium plating; nickel plating; tin plating (steel plate tin plating); copper plating, copper foil production and copper foil post-treatment, aluminum foil anodization applied in liquid conductivity generation tank.

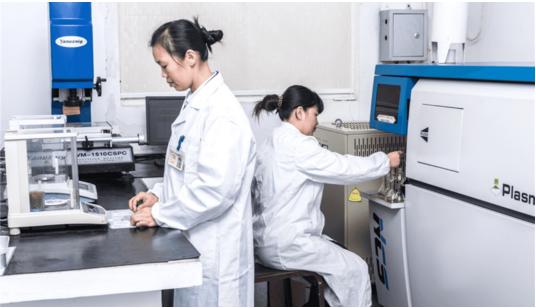

Quality checks:

Accelerated Life Test, Coating Thickness Test, Coating composition test, Conduct electricity conductivity testing,

Surface roughness test, Helium Leak Detection Test, Contact Resistance Test, Electrochemical Performance Test, and other tests.

JOINTING R&D

Improving current efficiency and prolonging service life are the core technical indicators of DSA titanium electrodes. Different industries have different requirements for the performance of titanium electrodes. Even if the same industry uses the same system of electrocatalytic coatings for different electrolytes, it may not be possible. Bring the ideal use effect. Based on years of accumulated R&D and production experience and a high-level technical team, the company can tailor a coating system that meets its own production environment for target customers to meet the differentiated needs of different industries or different customers in the same industry.

Development of electrode materials for high chlorine evolution efficiency and long life. Development of electrode materials for high acidity and long life oxygen evolution. Development of new electrode materials for mixed acid systems.

Development of high-oxygen ultra-base metal electrode materials Development of electrode materials in special fields