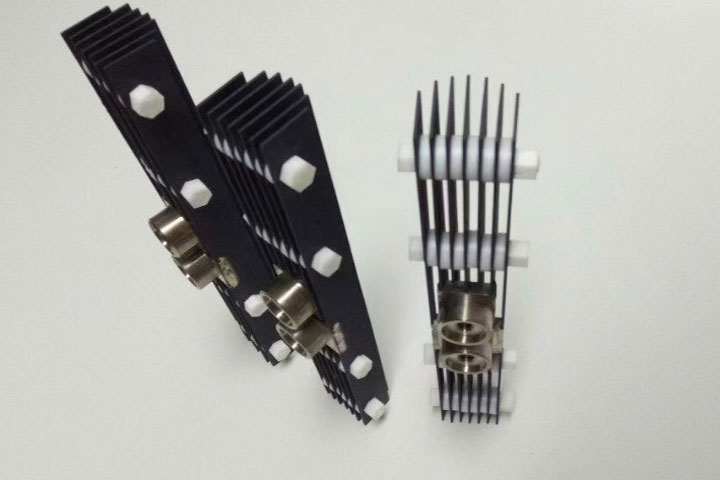

High Speed Electroplating Titanium Anode

Substrate: Titanium Grade 1 Sheet

Coating: Ir-Ta-X

Current density: Current density: 200-500A/m²

High-speed plating is the process of plating with a current density more than 10 times higher than the general static immersion plating method, which is characterized by high current density, i.e., high ultimate current density and high liquid flow rate, up to 2 m/s. The high liquid flow rate can reduce the effective thickness of the diffusion layer, thus increasing the cathode current density without reducing the cathode current efficiency. Wire plating.

High-speed zinc plating methods and characteristics

The current high-speed zinc plating solution is basically a sulfate plating solution. The main components of the solution are zinc sulfate, sodium sulfate, sulfuric acid, etc. It is characterized by stable performance, high current efficiency, fast deposition, and high current density, which makes it suitable for high-speed electroplating on wire and strip. However, the disadvantage of using sulfate plating solution is coarse crystallization and poor dispersion ability.

Types of high-speed zinc plating

Parallel flow method

The parallel flow method means that the cathode and anode are kept at a certain distance from each other.

The electrolyte flows in a direction parallel to the cathode element. It requires a small and equal distance between cathodes and anodes and is generally suitable only for simple shapes with external surfaces and flat surfaces.

In the parallel flow method, the plating solution flows at high speed, the anode does not move, and the cathode is pulled at high speed.

Jet method

The jet method is a method in which the electrolyte is continuously sprayed through a nozzle onto the cathode surface for plating. It is characterized by using high current density locally and is most effective for selective plating (small area local plating).

Types of zinc (tin) plating solution for strip steel plating.

|

Electrogalvanized(EGL) |

Tin Electroplating(ETL) | |||

| Electrolyte type | Zn | Zn-Ni | PSA | MSA |

| temperature/℃ | 45~70 | 45~60 | 50~60 | 40~65 |

| Ph | <1 | <1 | ||

| sulfuric acid g/l | 10~100 | 10~50 | 40~70 | <10 |

| Methyl sulfonic acid g/l | 30~60 | |||

| Phenol sulfonic acids /l | 15~60 | |||

| Sn²+ (g/l) | 27~29 | |||

| Zn as ZnSO4 /(g/l) | 60~125 | 30~60 | ||

| Na as Na2SO4 | 0~100 | |||

| Ni as Ni2SO4 (g/l) | 40~60 | |||

| Fe /(g/l) | <10 | <10 | <10 | <10 |

| chloride ug/g | <50 | <50 | ||

| fluoride ug/g | <2 | <2 | ||

| organic additive | ||||

| ENSA/(g/l) | 2.5~3.5 | |||

| EN/ g/l | 4.5~5.5 | |||

| Crystal scouring agent /ml | 40~60 | |||

| antioxidant ml/l | 15~25 | |||

| current density A/m2 | 5k~15k | 5k~12k | 2k~4k | 2k~7k |