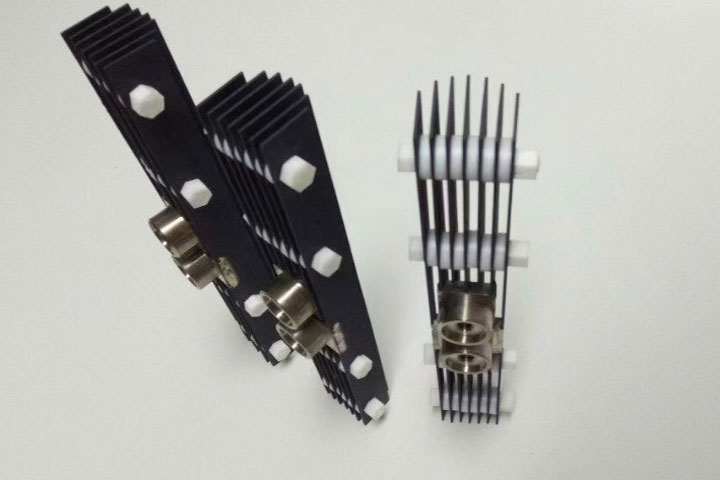

Titanium Anodes for Precious Metal Plating

Substrate: Titanium Grade 1 Sheet

Coating: Ir-Ta-X

Current density: Current density: 200-500A/m²

Titanium anode (MMO) is made of precious metal iridium salt coated on titanium substrate by high-temperature sintering, widely used in electroplating (deep hole high demand copper plating in the circuit board industry, electroplating gold), electrolysis and other wet metallurgical behavior. The preparation and application of electrodes has been quite mature, compared to the traditional platinum-plated electrodes in the alkaline copper plating process, titanium anodes have the advantages of platinum-plated electrodes can not be compared to.

1、Technical characteristics

High current efficiency, excellent antibacterial corrosion performance; long electrode life; can withstand higher current density, operating current density; <10000A/M2 belongs to the oxygen precipitation anode with industrial pure titanium as the base

2、High catalytic activity

As we all know, the platinum-plated electrode is a high peroxide potential (1.563V, relative to mercurous sulfate) electrode, while the MMO anode is a low oxygen precipitation peroxide potential (1.385V relative to mercurous sulfate) electrode, which is easier to precipitate oxygen in the anode precipitation area. Therefore, the tank pressure is also relatively low during electrolysis, which saves more power. This phenomenon is clearly reflected in the copper foil post-treatment alkaline treatment alkaline copper plating wall.

3、 High-cost performance

MMO anode has the same service life as a platinum-plated electrode (coating thickness 3.5mm), and the price of MMO anode is about 80% of the platinum-plated electrode. MMO electrode has better electrochemical stability in alkaline copper plating electrolytes, and it has excellent electrolytic activity and durability. From the analysis of the cost of our MMO anode and PT electrode, it is obvious that the MMO electrode is economical.

4. Since the application of copper in printed circuit boards requires the use of pulse-period reversal (PPR) technology, we know that the use of platinum-plated insoluble anodes is prohibited (the presence of oxides in the sulfuric acid electrolyte in such a current loop will strip the platinum layer after a period of time). However, the use of dimensionally stable anodes avoids this phenomenon and allows the insoluble anode technology to successfully achieve superior performance advantages in this application.

5. Minimal anode maintenance. No need to stop the line to clean and replenish anodes, replace anode bags and recoat anodes (increased productivity and reduced labor costs).

6. The life of the insoluble anode depends on the type, working current density and contact with various plating chemicals.

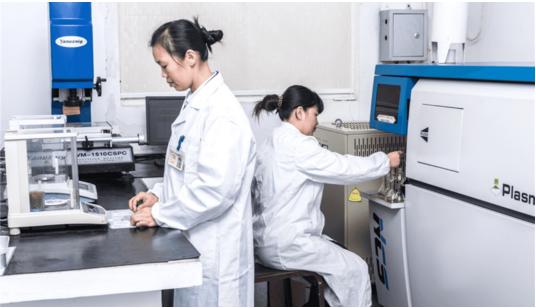

Quality checks:

Accelerated Life Test, Coating Thickness Test, Coating composition test, Conduct electricity conductivity testing,

Surface roughness test, Helium Leak Detection Test, Contact Resistance Test, Electrochemical Performance Test and other test.

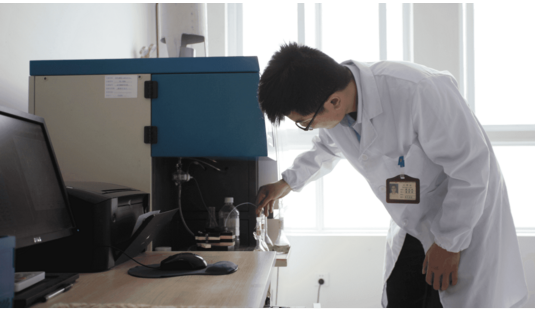

JOINTING R&D

Improving current efficiency and prolonging service life are the core technical indicators of DSA titanium electrodes. Different industries have different requirements for the performance of titanium electrodes. Even if the same industry uses the same system of electrocatalytic coatings for different electrolytes, it may not be possible. Bring the ideal use effect. Based on years of accumulated R&D and production experience and a high-level technical team, the company can tailor a coating system that meets its own production environment for target customers to meet the differentiated needs of different industries or different customers in the same industry.

Development of electrode materials for high chlorine evolution efficiency and long life. Development of electrode materials for high acidity and long-life oxygen evolution. Development of new electrode materials for mixed acid systems.

Development of high-oxygen ultra-base metal electrode materials Development of electrode materials in special fields