Desalination Titanium Anode

Substrate: Titanium Grade 1 Sheet

Coating: Ru-Ir-X

The electrolytic seawater sodium hypochlorite generating device uses natural seawater and adopts high-speed electrolysis to produce highly active sodium hypochlorite solution on site. The sodium hypochlorite solution is delivered to the dosing point as a biocide through dehydrogenation storage to effectively kill microorganisms, sea creatures, algae and germs in the water body and prevent blockage in the circulating water pipeline and condenser system. The complete set of equipment consists of seawater booster pump, automatic cleaning filter, electrolytic seawater sodium hypochlorite generator, storage, hydrogen discharge device, dosing pump, acid washing equipment, electrolysis power supply and automatic control operation system.

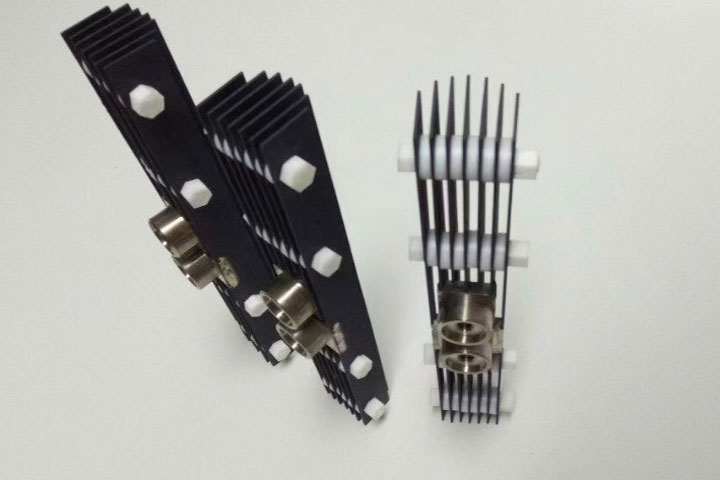

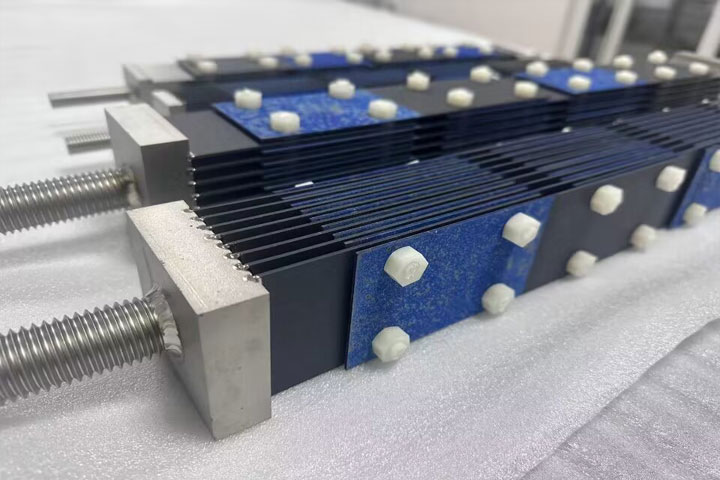

The core of the electrolysis device is the electrolyzer, which is usually made of titanium substrate coated with precious metal oxides such as platinum, ruthenium, iridium and rhodium as the anode and corrosion-resistant special metal materials as the cathode, forming a closed electrolyzer vessel, and the electrode material is one of the core components. Stable performance, strong bonding between coating and substrate, and long service life.

Product Specifications: Customized according to customer drawings

Coating: Ruthenium-iridium-X coating

Lifetime: 2-10 years

Inverted pole: Yes

Chlorination potential: less than or equal to 1.13V

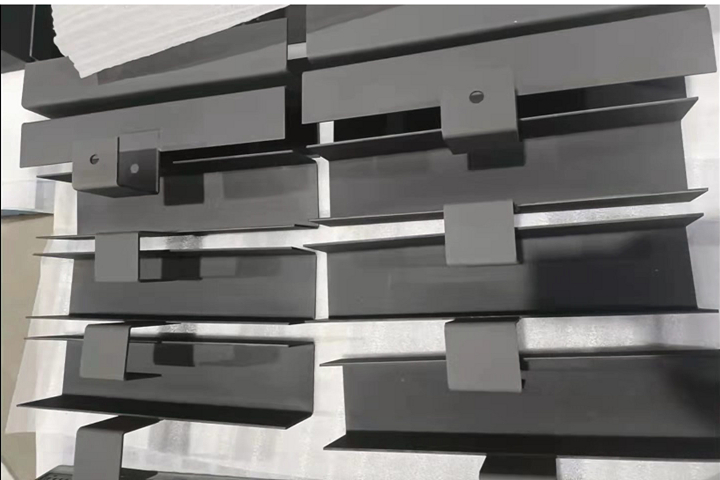

Product shape: plate, rod, sheet, wire, mesh, tube, ring, strip, mesh basket, etc.

Various complex shapes can be customized according to customer requirements to meet product design needs

The design of titanium electrode type based on the following considerations.

- Requirements for anode in the installation of titanium electrode electrolyzer

- Titanium electrode process conditions, such as electrolyte (liquid) composition, temperature, current density, service life, etc.

- Mechanical load of titanium electrode

- Conductivity of titanium electrode substrate material

Application:

Applicable to coastal power station and nuclear power station circulating water, chemical, petrochemical and offshore drilling platform, seawater desalination, ship ballast water treatment and other fields.

Advantages:

- High current efficiency, good energy-saving effect

- Excellent anti-corrosion performance

- After the active layer is deactivated, it can be recoated and the substrate can be reused

- Long service life of electrode

- Titanium electrode is light in weight and has good dimensional stability

- Can be made into any complex shape and size to meet the actual demand

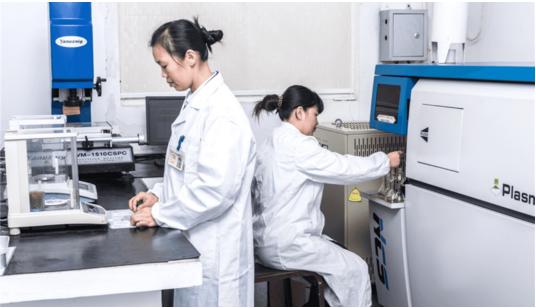

Quality checks:

Accelerated Life Test, Coating Thickness Test,Coating composition test,Conduct electricity conductivity testing ,

Surface roughness test, Helium Leak Detection Test, Contact Resistance Test, Electrochemical Performance Test and other test.

JOINTING R&D

Improving current efficiency and prolonging service life are the core technical indicators of DSA titanium electrodes. Different industries have different requirements for the performance of titanium electrodes. Even if the same industry uses the same system of electrocatalytic coatings for different electrolytes, it may not be possible. Bring the ideal use effect. Based on years of accumulated R&D and production experience and a high-level technical team, the company can tailor a coating system that meets its own production environment for target customers to meet the differentiated needs of different industries or different customers in the same industry.

Development of electrode materials for high chlorine evolution efficiency and long life. Development of electrode materials for high acidity and long life oxygen evolution. Development of new electrode materials for mixed acid systems.

Development of high-oxygen ultra-base metal electrode materials Development of electrode materials in special fields