EDI desalination titanium anode

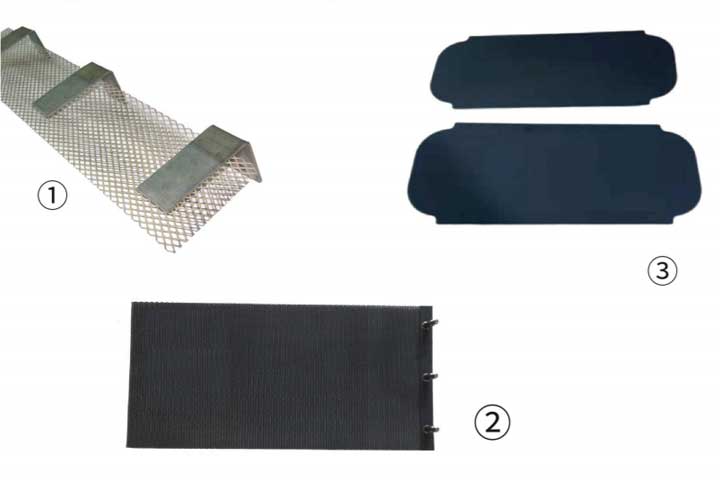

Substrate: Titanium Grade 1 Sheet

Coating: Ru-Ir-X

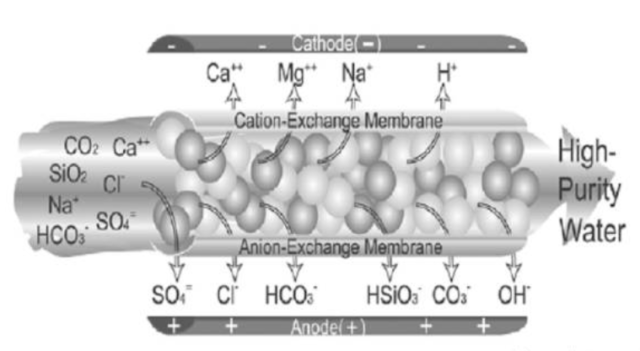

EDI, also known as continuous electrodesalination technology, scientifically integrates electrodialysis technology and ion exchange technology to achieve deep purification and desalination of water through the selective permeation of cations and anions by anion and cation membranes and the exchange of ions in water by ion exchange resins under the action of electric field to achieve the directional migration of ions in water. And through the hydrogen ions and hydroxide ions generated by water electrolysis to the filling resin for continuous regeneration, the process does not need acid and alkali chemicals, can be continuous production of high-purity water.

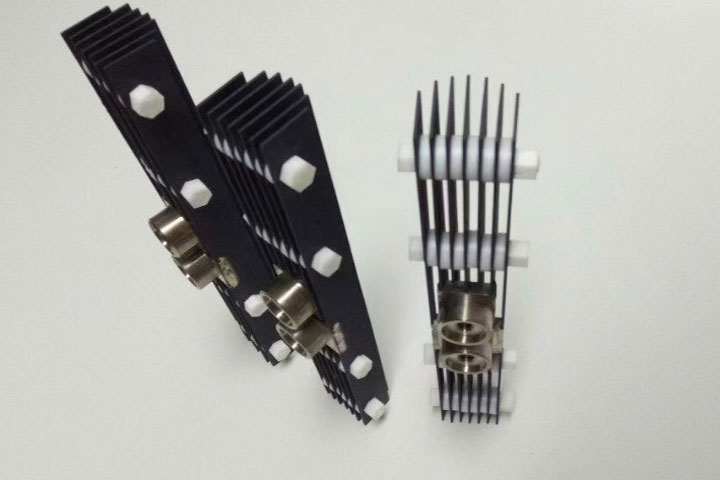

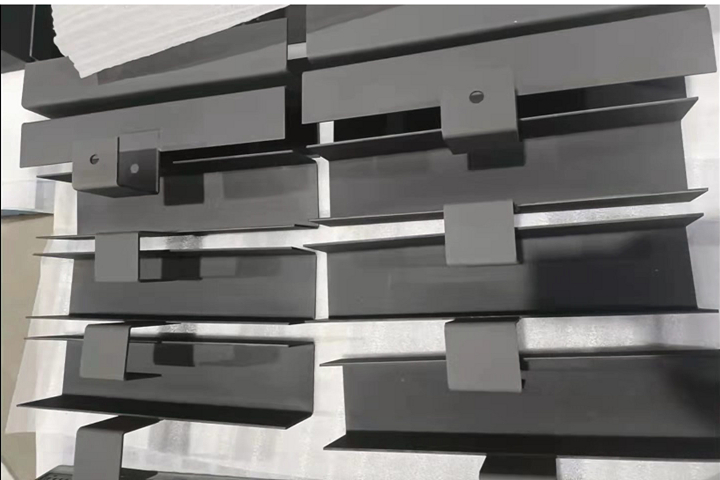

The main body of the electrode plate is carved by CNC engraving machine, with high strength, excellent performance, long life, flat structure and generous appearance. After testing several coating formulas by our product development center, we choose the most excellent ruthenium-based multi-mixed metal oxide coating formula with high electrolytic efficiency and very stable performance.

EDI titanium anode standard size:

400×1600mm、800×1600mm、400×800mm、200×600mm、200×400mm, etc.

Size can also be customized according to customer requirements

EDI desalination process:

The core of EDI is actually an anion and cation exchange resin filled in the fresh water chamber of electrodialysis.

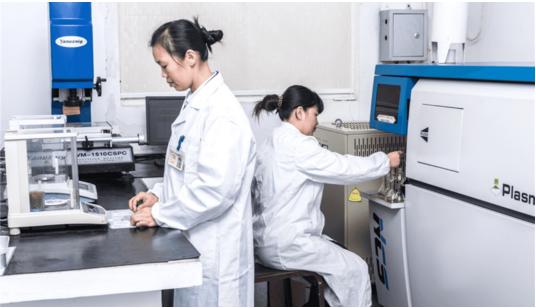

Quality checks:

Accelerated Life Test, Coating Thickness Test,Coating composition test,Conduct electricity conductivity testing ,

Surface roughness test, Helium Leak Detection Test, Contact Resistance Test, Electrochemical Performance Test and other test.

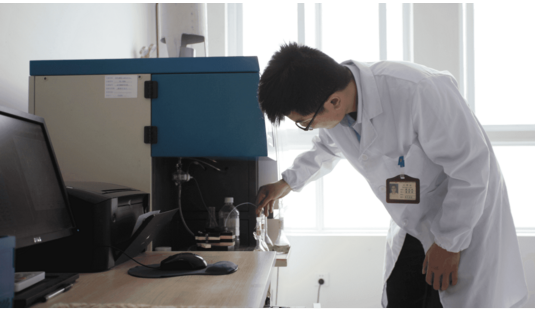

JOINTING R&D

Improving current efficiency and prolonging service life are the core technical indicators of DSA titanium electrodes. Different industries have different requirements for the performance of titanium electrodes. Even if the same industry uses the same system of electrocatalytic coatings for different electrolytes, it may not be possible. Bring the ideal use effect. Based on years of accumulated R&D and production experience and a high-level technical team, the company can tailor a coating system that meets its own production environment for target customers to meet the differentiated needs of different industries or different customers in the same industry.

Development of electrode materials for high chlorine evolution efficiency and long life. Development of electrode materials for high acidity and long life oxygen evolution. Development of new electrode materials for mixed acid systems.

Development of high-oxygen ultra-base metal electrode materials Development of electrode materials in special fields