waste water titanium anode

Substrate: Titanium Grade 1 mesh

Coating: Ru-Ir-X,Pt-X

With the development of industry, the discharge of organic wastewater is increasing, especially the wastewater discharged from chemical, food, pesticide and pharmaceutical industries with high concentration, high chromaticity and toxicity, containing a large number of biodegradable components, which seriously pollute the rivers, lakes and seas. The new technology of electrolysis water treatment has no need to add chemicals, the equipment is small in size, does not occupy a large area, and does not produce secondary pollution, and has been used to treat organic pollution wastewater containing hydrocarbons, alcohols, aldehydes, ethers, phenols, etc.

To reduce COD, it mainly relies on the oxidation reaction on the anode surface, which is directly on the surface of the anode to oxidize and degrade the organic matter. Therefore, if the water contains more organic matter, titanium anode should be used, which is more beneficial to the decomposition of organic matter in water.

ODEVS has designed and developed an iridium-tantalum anode plate with an activation layer, which is coated with an activation layer composed of tin and antimony oxides on the titanium substrate. Mainly in the organic wastewater COD degradation treatment reflects its unique superiority, can make the organic matter directly in the anode surface is oxidized to CO2 and water, also prevent the original oxygen atoms into the coating internal damage coating, so as to enhance the anode life.

Advantages of titanium anode

Break the tradition, technological innovation。Although this method has shown good results in the treatment of industrial wastewater, the composition of different wastewater varies, and the combination with other treatment methods needs to be reasonably selected according to different discharge standards.

With high oxygen precipitation overpotential, the anode potential is higher than the decomposition potential of organic matter

The titanium substrate can be reused after the coating has lost its activity, saving costs

Can be used at high current density, high productivity and long working life

Reduced weight of electrode compared with lead anode, which greatly reduces workers’ workload

High cost performance and no pollution of working environment

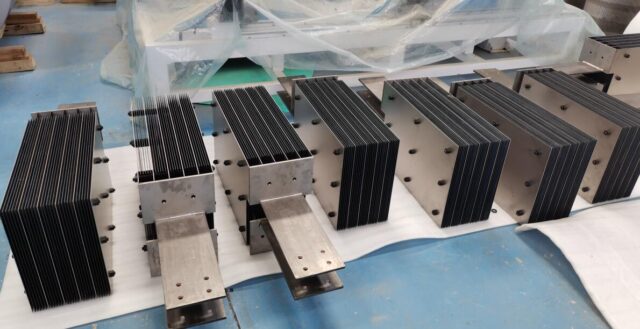

Anode shapes

Plate type, tube type, mesh type and other forms are available for customers to choose

It can also be customized according to customers’ specific needs.

Application:

It has been widely used in wet metallurgy projects (Cu, Ni, Zn, etc.), electroplating, electrolysis,

electrodeposition, wastewater treatment, COD degradation (electrolytic preparation of organic and inorganic substances), high purity

The application field is very wide and cannot be replaced by many other electrode materials.

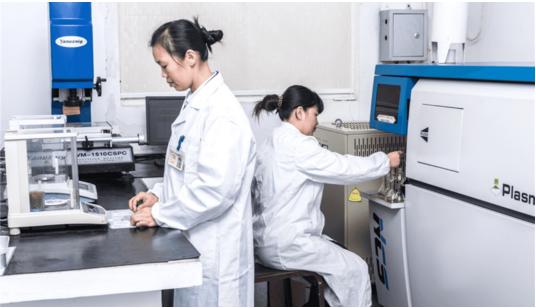

Quality checks:

Accelerated Life Test, Coating Thickness Test,Coating composition test,Conduct electricity conductivity testing ,

Surface roughness test, Helium Leak Detection Test, Contact Resistance Test, Electrochemical Performance Test and other test.

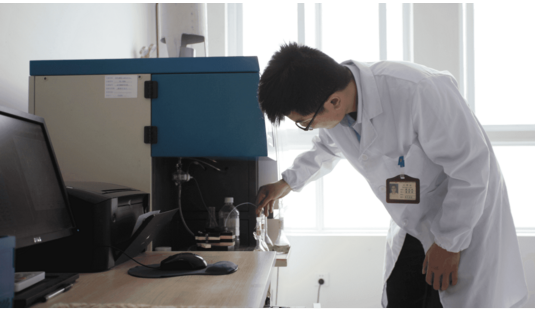

JOINTING R&D

Improving current efficiency and prolonging service life are the core technical indicators of DSA titanium electrodes. Different industries have different requirements for the performance of titanium electrodes. Even if the same industry uses the same system of electrocatalytic coatings for different electrolytes, it may not be possible. Bring the ideal use effect. Based on years of accumulated R&D and production experience and a high-level technical team, the company can tailor a coating system that meets its own production environment for target customers to meet the differentiated needs of different industries or different customers in the same industry.

Development of electrode materials for high chlorine evolution efficiency and long life. Development of electrode materials for high acidity and long life oxygen evolution. Development of new electrode materials for mixed acid systems.

Development of high-oxygen ultra-base metal electrode materials Development of electrode materials in special fields