Electrolytic Copper Foil

Electrolytic Copper Foil

Overview:

The global electrolytic copper foil market has witnessed huge potential growth opportunities in the past few years. Electrolytic copper foils are utilized for applications including Li+ batteries for cell phones, laptops, and other consumer electronics.

These foils are employed as negative electrode current collectors. But why did we choose a titanium anode for this processing?

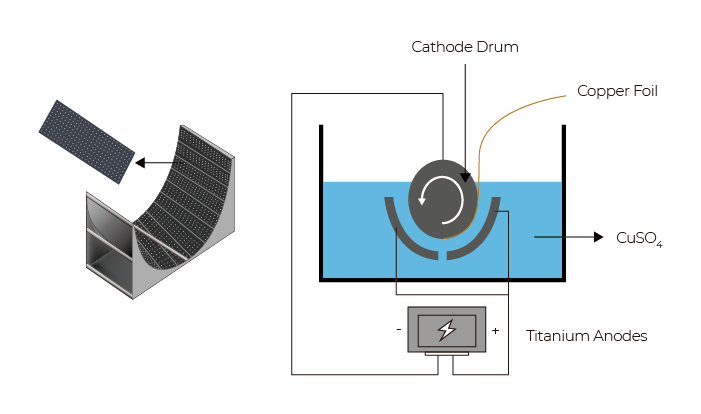

Electrodeposited copper foil is manufactured through the deposition of copper ions, onto the cathode drum via electrolysis. High-purity copper is first dissolved in acid to form a copper electrolyte solution, this copper electrolyte is then pumped into the electrolyzer where an electrically charged rotating titanium drum is partially immersed. Dimensionally stable anodes (DSAs) are fixed around the drum. As an electric field is applied between electrodes, a thin film of copper will be electrodeposited onto the drum surface. The slower the drum speed, the thicker the copper gets, and vice versa.

Anodes:2H2O→O2↑ + (4H+) + 4e–

Cathode:Cu2+ + 2e–→Cu

If you want to get information on these technologies, please visit: