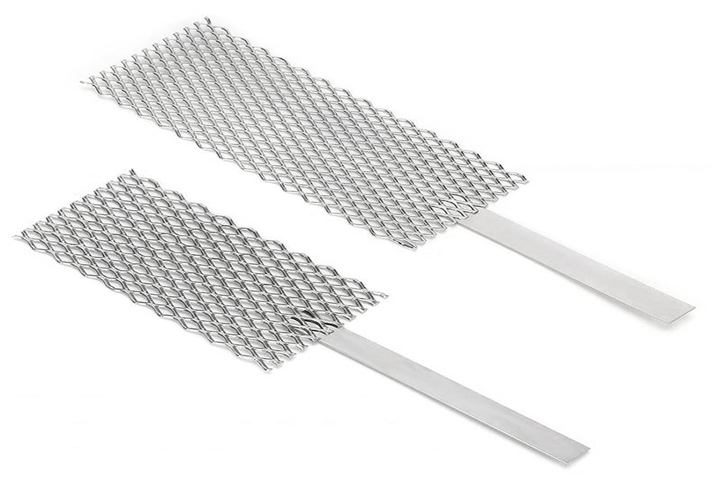

Types Of Electrodialysis electrode

Titanium platinum-coated electrode, titanium-coated ruthenium electrode, graphite electrode, stainless steel electrode;

Specifications of Electrodialysis electrode

800×1600mm, 400×1600mm, 400×800mm, 340×640mm

Characteristics of different electrode materials

Titanium platinized electrode:

The corrosion resistance is quite good, and it can be used under very harsh conditions, but the price of platinum is expensive and the resources are few, which limits its promotion in China.

Titanium-coated ruthenium electrode: It is a compound of ruthenium (Ru), iridium (Ir), and titanium (Ti) coated on a titanium substrate, and its mixed oxide is formed after high-temperature treatment; due to ruthenium (Ru), iridium (Ir), The ionic radius of titanium (Ti) is very close, and the lattice structure and space group belong to the same type, so it can form a solid solution of RuO2-IrO2-TiO2 in the co-oxidation of heat treatment, which has excellent corrosion resistance and is very suitable as an electrode material.

Graphite electrode: Graphite electrode is easily corroded, mainly due to chemical corrosion and mechanical wear; when graphite is used as an anode, due to anodic oxidation, graphite is oxidized to CO2 or CO, and its crystal structure is destroyed and damaged; in electrodialysis device, The loss of medium graphite electrode is mainly caused by mechanical action. The high flow rate of polar water has a strong scouring effect on graphite. On the other hand, the gas generated by the electrode reaction has an impact on graphite. Coupled with electrochemical corrosion, it often causes graphite Particle exfoliation pollutes water quality and even block polar water channels; with the advent of titanium-coated ruthenium electrodes, graphite electrodes have been gradually eliminated.

Stainless steel electrode: Generally speaking, stainless steel is only used as a cathode and cannot be used as an anode. Otherwise, because the natural water contains more chloride ions, the anode of stainless steel will dissolve and generate divalent iron, nickel, and chromium ions.

How to choose electrodes?

The correct selection of electrode materials is of great significance to prolong the service life of electrodes, reduce system investment and operating costs, and choose electrodes of different materials for different water quality:

- For natural water with chloride as the main component, titanium-coated ruthenium electrodes can be preferred.

- For natural water with sulfate as the main component, lead plate, stainless steel, and titanium-coated ruthenium electrodes can be preferred.

- For natural water with calcium bicarbonate as the main component, stainless steel, and titanium-coated ruthenium electrodes can be preferred.

- For natural water with mixed ions, titanium-coated ruthenium, graphite, and titanium-coated platinum electrodes can be preferred.

Our Advantages

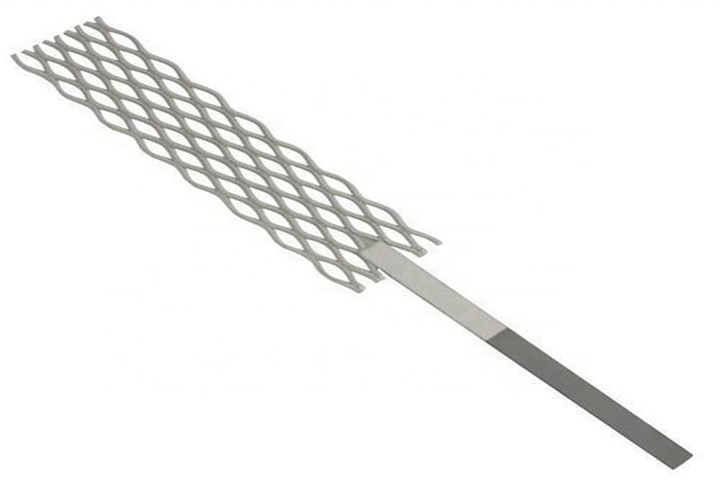

After special processing technology, the coating is firmly combined with the substrate, with good electrocatalytic performance, strong corrosion resistance and long service life, which can fully meet the use of electrodialysis conductors.