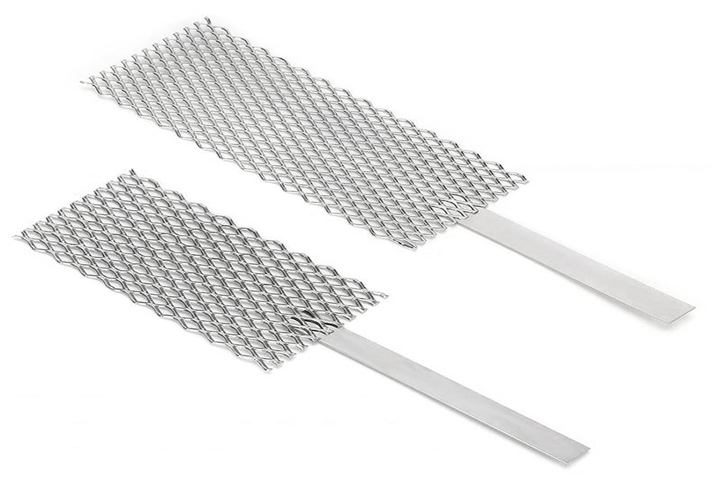

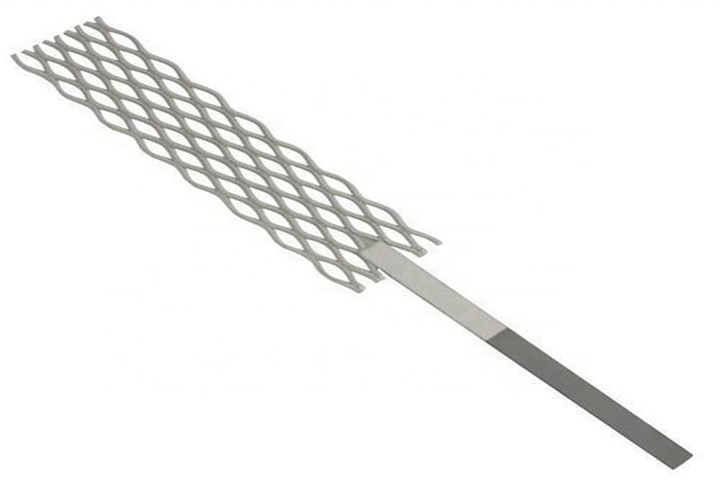

Platinum-coated titanium anodes

Substrate: Titanium Grade 1 mesh

Coating: Pt-Ti

Coating thickness: 0.5μm-5μm

MMO platinum plated titanium anodes are available as DSA insoluble anodes for the plating industry in various sizes of plated titanium baskets and titanium laths.

-

Substrate Metal Chemical Composition:

| Grade | N | C | H | Fe | O | Ti |

| Gr1 | 0.03 | 0.08 | 0.015 | 0.20 | 0.18 | bal |

-

MMO Coating: Platinum 0.5~5 micron

| Coating | Oxygen revolution potential | Suitable working environment |

| Platinum | <1.68V | Fluoride ion< 200PPM, PH:1-11 |

-

Working Parameters for Platinum Coating:

| Current density | Temperature | Chlorine concentration | Polarity reversal | Reversal frequency |

| <2000A/m2 | 40-60°C | About 30grams/liter | suitable | 2-4 hours |

Features

1、Stable and uniform plating layer, longer service life

2、Higher current resistance, higher plating efficiency

3、Low working voltage, low energy consumption

4、No pollution of plating solution, realize clean production in plating industry

5, lower cost than pure gold and platinum anodes, but similar electrochemical properties

6, high overpotential for oxygen release reaction and low overpotential for hydrogen release reaction

Applications.

Precious metal plating (Ag, Au, Rh, Pd)

Hard chromium plating (Cr6+): piston rings

Base metal plating (Cu, Zn, Ni)

How to use platinum titanium anode?

1.Before using platinum plated titanium electrode, you should first exclude (must test) the presence of “chloride” ions and “phosphate” ions in the plating solution, to confirm that the chemical composition of platinum plating does not corrode the titanium electrode, before safely using platinum plated titanium electrode.

Otherwise, the base material at the bottom of the platinum plated titanium electrode will be seriously corroded, the platinum plating layer will fall off and the service life will be shortened. Do not use hard inscription additives and recycled industrial inscription pastries containing chloride ions.

2.Reasonable choice of the best process: platinum titanium electrode plating current density is best to choose below 50A/dm2, tank pressure below 10V, otherwise affect the anode life will cause serious galvanic corrosion, dissolution, plating off, try to choose no solid oxide generation process of anodic oxidation reaction.

Avoid oxide thickening passivation affect the conductivity of platinum-plated titanium electrodes. Anode breakdown is based on the properties of titanium itself, when the trough pressure is greater than 10V, the platinum-plated titanium surface begins to dissolve slightly.

After breakdown, the trough pressure of 12V is not visible, only about 11V, no current can be added and the anode is destroyed, so the safe use of platinum-plated titanium electrode trough pressure is set at 10V or less.

3.Generally, the surface area of cathode should be smaller than anode (area below liquid surface), when the area of anode is smaller than the area of cathode, titanium electrode can’t be used, because the anode is easy to be broken through.

4.The tank pressure will increase with the increase of the impedance of the plating tank. When the tank pressure exceeds 10V, you should not continue to increase the current, but should adjust the current appropriately, such as: adjusting the current downward by 10% and extending the plating time by 10%.

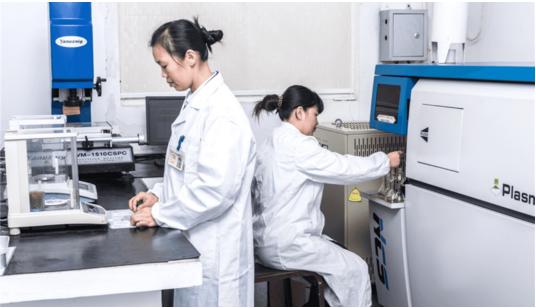

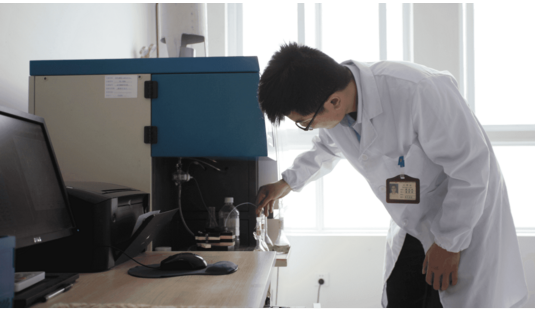

Quality checks:

Accelerated Life Test, Coating Thickness Test,Coating composition test,Conduct electricity conductivity testing ,

Surface roughness test, Helium Leak Detection Test, Contact Resistance Test, Electrochemical Performance Test and other test.

JOINTING R&D

Improving current efficiency and prolonging service life are the core technical indicators of DSA titanium electrodes. Different industries have different requirements for the performance of titanium electrodes. Even if the same industry uses the same system of electrocatalytic coatings for different electrolytes, it may not be possible. Bring the ideal use effect. Based on years of accumulated R&D and production experience and a high-level technical team, the company can tailor a coating system that meets its own production environment for target customers to meet the differentiated needs of different industries or different customers in the same industry.

Development of electrode materials for high chlorine evolution efficiency and long life. Development of electrode materials for high acidity and long life oxygen evolution. Development of new electrode materials for mixed acid systems.

Development of high-oxygen ultra-base metal electrode materials Development of electrode materials in special fields