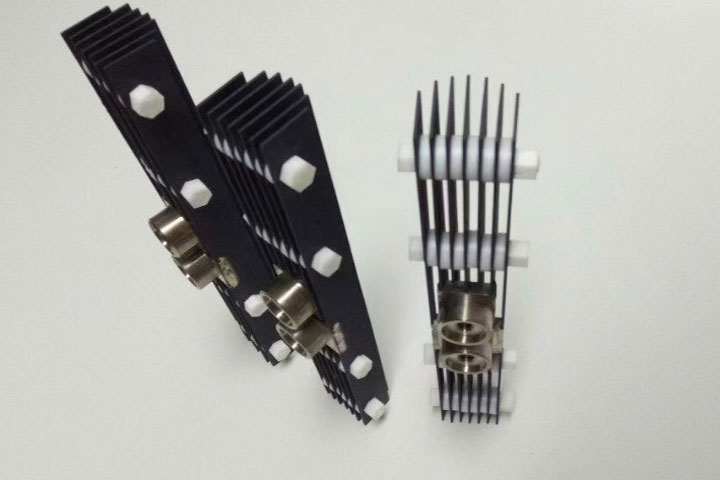

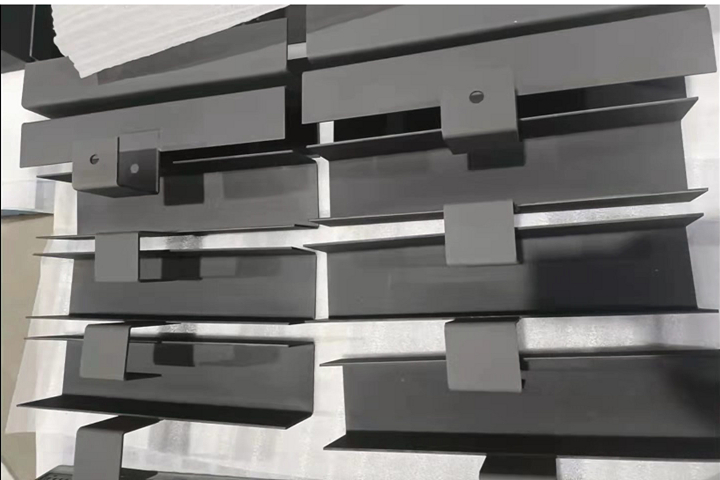

Circulating water treatment anode

Substrate: Titanium Grade 1 basket

Coating: Ru-Ir-X

The industrial circulating cooling water system in the process of operation, due to water evaporation, the wind blowing loss, etc. makes the circulating water constantly concentrated, which contains salts that exceed the standard, anions and cations increase, pH value significantly changed, resulting in water quality deterioration, while the temperature of circulating water, PH value and nutrients are conducive to the reproduction of microorganisms, cooling towers on sufficient sunlight is the ideal place for algae growth. And scaling control and corrosion control, microbial control, etc., the inevitable need for circulating water treatment.

Electrolysis treatment of industrial circulating cooling water, through electrolysis, the formation of high concentrations of hydroxide near the cathode, this high PH environment, so that the scaled minerals pre-scaling, and precipitation from the water, played a role in softening the water. At the same time, hydroxyl radicals are generated at the anode site and convert chloride ions into free chlorine and some hydroxyl radicals into trace ozone, which provides a biocidal effect and plays a role in sterilization, disinfection, and algae control.

ODEVS designed and developed the titanium anode according to the three major problems in circulating water treatment: descaling, algae disinfection and sterilization, which has the characteristics of high oxygen precipitation and low chlorine precipitation potential, as well as high efficiency and long life.

Applications

Widely used in industry, agriculture, tourism, environmental protection, daily life and other fields, such as power plants, iron and steel plants, cement plants, petrochemical, electric power, pharmaceutical, food, paper printing, metallurgy, coal mining, machining, manufacturing, *** breeding, shopping malls, hotels, office premises, etc.

Central air-conditioning cooling water, to solve the problems of scaling, sludge deposition, and bacterial algae; such as factories, hotels, shopping malls, office buildings, institutional office buildings, etc.

Industrial use air pressure stations, and heating systems, to solve the problem of water system scale, rust, and corrosion, such as electronics factories, electronic circuit board factories, mold factories, and heating systems, etc.

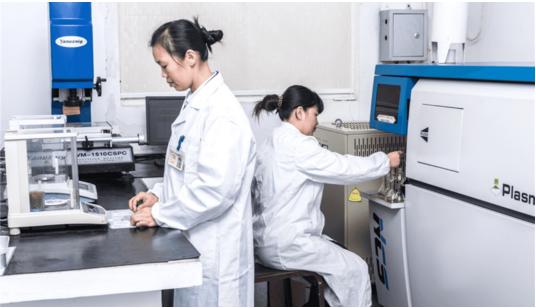

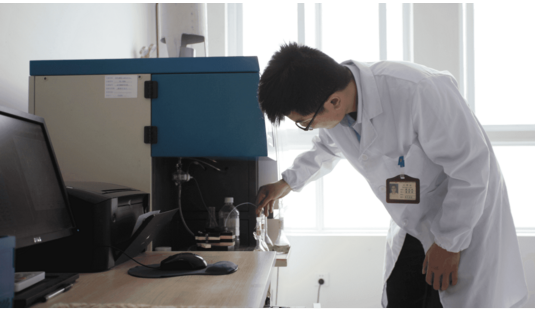

Quality checks:

Accelerated Life Test, Coating Thickness Test, Coating composition test, Conduct electricity conductivity testing,

Surface roughness test, Helium Leak Detection Test, Contact Resistance Test, Electrochemical Performance Test, and other tests.

JOINTING R&D

Improving current efficiency and prolonging service life are the core technical indicators of DSA titanium electrodes. Different industries have different requirements for the performance of titanium electrodes. Even if the same industry uses the same system of electrocatalytic coatings for different electrolytes, it may not be possible. Bring the ideal use effect. Based on years of accumulated R&D and production experience and a high-level technical team, the company can tailor a coating system that meets its own production environment for target customers to meet the differentiated needs of different industries or different customers in the same industry.

Development of electrode materials for high chlorine evolution efficiency and long life. Development of electrode materials for high acidity and long-life oxygen evolution. Development of new electrode materials for mixed acid systems.

Development of high-oxygen ultra-base metal electrode materials Development of electrode materials in special fields