fruit and vegetable machine disinfection

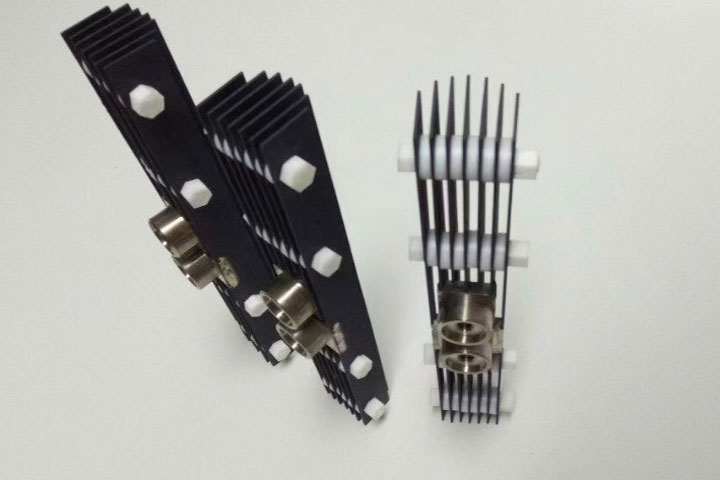

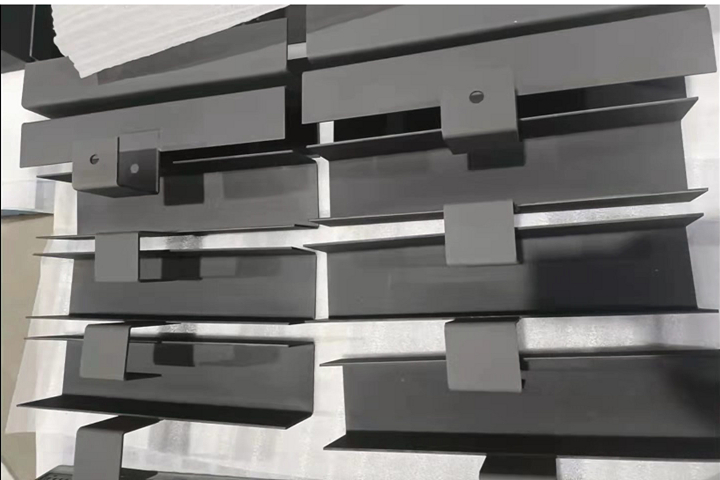

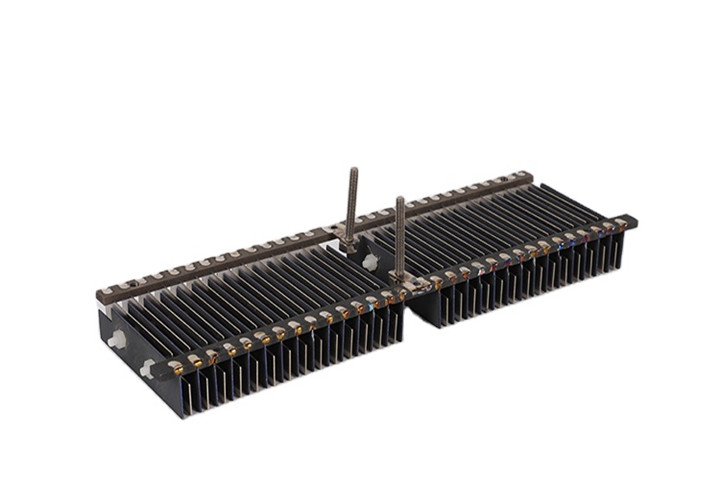

Substrate: Titanium Grade 1 Sheet

Coating: Ru-Ir-X

The titanium anode for disinfection of fruit and vegetable machine produced by Odevs uses special material coated titanium electrode, which is the essential core device of disinfection solution generator, with simple production process, low investment and quick effect. Water and salt are used as raw materials, and AC 220V power supply is used, which is convenient to take materials and simple to produce. The production of disinfection solution is stable and high, and the product has a long service life.

The sodium hypochlorite generated after treatment with titanium electrode is also able to decompose the trace pesticides remaining on agricultural and sideline products such as vegetables and fruits. It has a significant role in promoting the development of modern agriculture, fruit and vegetable packaging industry. Moreover, it does not cause serious corrosion to metal pipes as chlorine gas reacts with water to form hydrochloric acid.

In recent years, the production of mini sodium hypochlorite disinfectant generator has been increasing, light and easy to carry, so it is very popular. The mini sodium hypochlorite generator is suitable for sterilization of unclean drinking water, such as river water, well water, pond water, and is especially useful for field operations, field troops and areas where water supply systems are also bought.

Sodium hypochlorite can quickly kill various pathogenic bacteria and viruses, such as Escherichia coli, Staphylococcus aureus, hepatitis B virus, Bacillus subtilis black variant bacillus, etc. The disinfection solution can effectively prevent hepatitis, typhoid, cholera, dysentery and other infectious diseases by disinfecting and sterilizing daily household products.

Application:

Disinfection of tableware, tea sets, with better effect than high temperature disinfection.

Disinfection, cleaning and deodorization of kitchen utensils, bath tubs, sanitary ware.

Disinfection of items and clothes used by patients.

Disinfection of bottles and toys used by infants and children.

Surface disinfection of fruits, fish and vegetables.

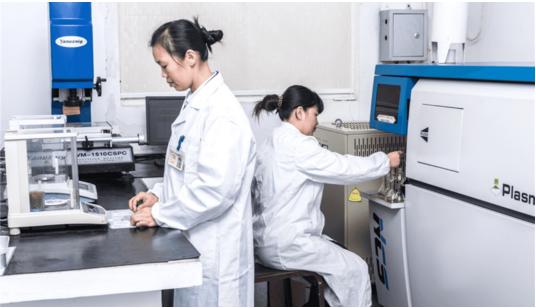

Quality checks:

Accelerated Life Test, Coating Thickness Test,Coating composition test,Conduct electricity conductivity testing ,

Surface roughness test, Helium Leak Detection Test, Contact Resistance Test, Electrochemical Performance Test and other test.

JOINTING R&D

Improving current efficiency and prolonging service life are the core technical indicators of DSA titanium electrodes. Different industries have different requirements for the performance of titanium electrodes. Even if the same industry uses the same system of electrocatalytic coatings for different electrolytes, it may not be possible. Bring the ideal use effect. Based on years of accumulated R&D and production experience and a high-level technical team, the company can tailor a coating system that meets its own production environment for target customers to meet the differentiated needs of different industries or different customers in the same industry.

Development of electrode materials for high chlorine evolution efficiency and long life. Development of electrode materials for high acidity and long life oxygen evolution. Development of new electrode materials for mixed acid systems.

Development of high-oxygen ultra-base metal electrode materials Development of electrode materials in special fields