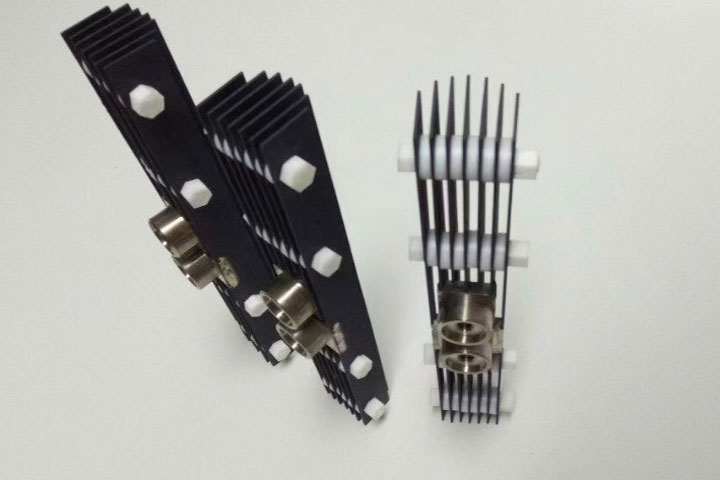

water treatment titanium anode

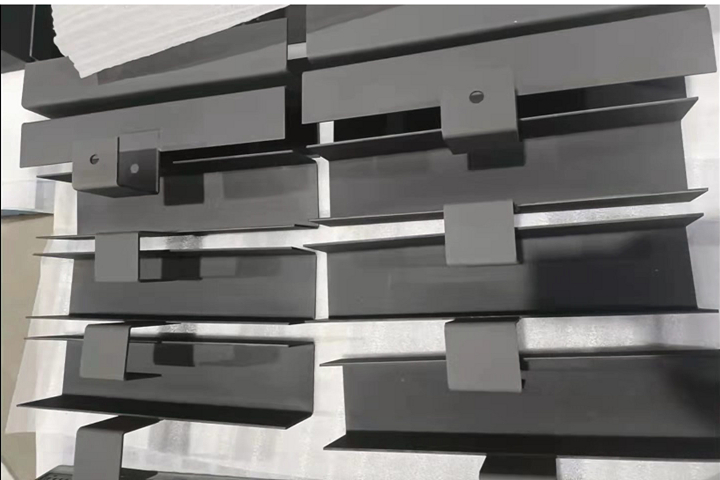

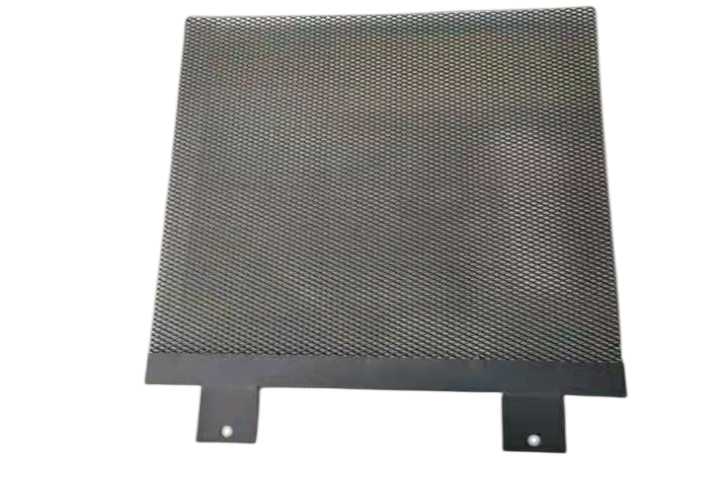

Substrate: Titanium Grade 1 mesh

Coating:Ru-Ir-X

Current density: Current density: 200-600A/m²

Oily wastewater is wastewater containing oil substances discharged during industrial production. Oil substances contained in oily wastewater include, for example, natural petroleum, petroleum products, tar and its fractions, as well as edible animal and vegetable oils and fats. The direct discharge of natural petroleum, petroleum products, tar, and its fractions causes large pollution to water bodies and needs to be purified and treated before discharge.

Electrochemical technology uses electrolysis as a means to achieve the redox of substances by controlling the electrode potential. Its principle of action is: in a piece of specific electrochemical reaction equipment, through the electrode reaction and the resulting series of chemical reactions, electrochemical processes, physical processes, etc., so that the pollutants within the oilfield wastewater to achieve the purpose of degradation and transformation, and has the following major characteristics.

- The electrochemical redox process produces -OH which can directly react with organic pollutants in the wastewater and degrade them into carbon dioxide, water and simple organic matter with almost no secondary pollution.

- Electrochemical technology can be carried out at room temperature and pressure, with high energy efficiency and a high degree of controllability of the reaction, which is convenient for industrial automation.

- Electrochemical technology can be treated alone or combined with other treatment methods, and separate treatment can improve the biodegradability of wastewater.

- Simple operation, reasonable price, simple equipment, small footprint and low operation and maintenance cost.

The main corrosion factor of today’s secondary recovery wells is caused by sulfate-reducing bacteria (SRB). oilfield wastewater quality is suitable for SRB growth, leading to massive reproduction and causing corrosion perforation of wastewater pipelines and oil casing. the metabolite of SRB, FeS precipitation, can cause formation blockage and a decrease in water injection, which directly affects crude oil production. Therefore, sterilization treatment of oilfield reinjection water is an important step in secondary adoption technology.

The initial bacterial content of SRB in the oil field was 6*10 3/ml, and after 3 min of electrolysis, the sulfate-reducing bacteria content in the wastewater was only 6/ml, and the sterilization rate was as high as 99.9%. As the current intensity increases, the distance between the electrode plates increases, and the voltage between the plates increases, which is more favorable to kill the sulfate-reducing bacteria.

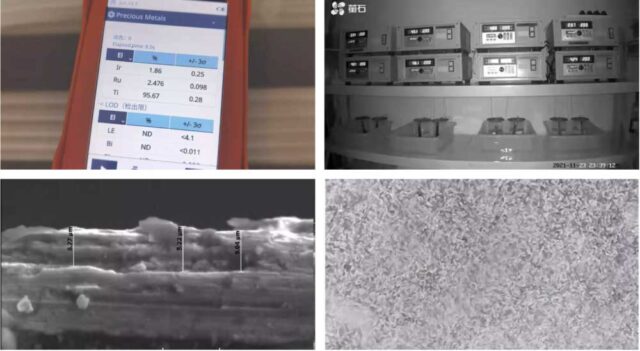

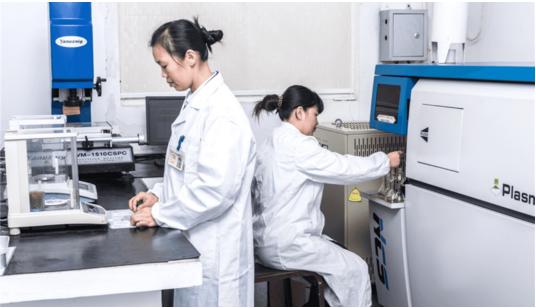

Quality checks:

Accelerated Life Test, Coating Thickness Test, Coating composition test, Conduct electricity conductivity testing,

Surface roughness test, Helium Leak Detection Test, Contact Resistance Test, Electrochemical Performance Test, and other tests.

JOINTING R&D

Improving current efficiency and prolonging service life are the core technical indicators of DSA titanium electrodes. Different industries have different requirements for the performance of titanium electrodes. Even if the same industry uses the same system of electrocatalytic coatings for different electrolytes, it may not be possible. Bring the ideal use effect. Based on years of accumulated R&D and production experience and a high-level technical team, the company can tailor a coating system that meets its own production environment for target customers to meet the differentiated needs of different industries or different customers in the same industry.

Development of electrode materials for high chlorine evolution efficiency and long life. Development of electrode materials for high acidity and long-life oxygen evolution. Development of new electrode materials for mixed acid systems.

Development of high-oxygen ultra-base metal electrode materials Development of electrode materials in special fields