Sodium hypochlorite generator

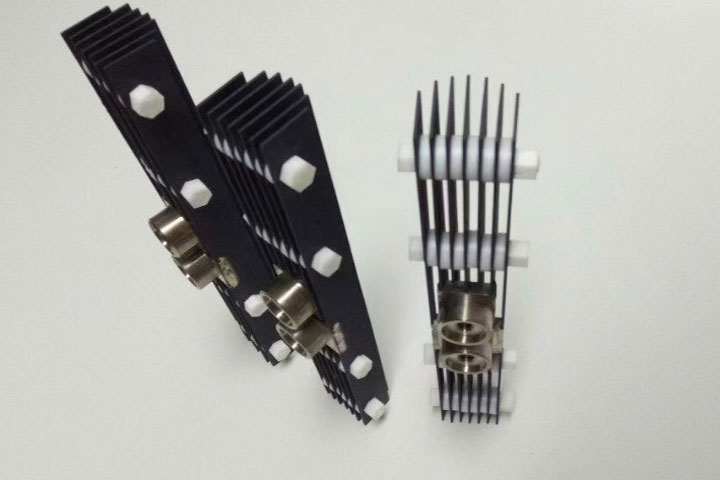

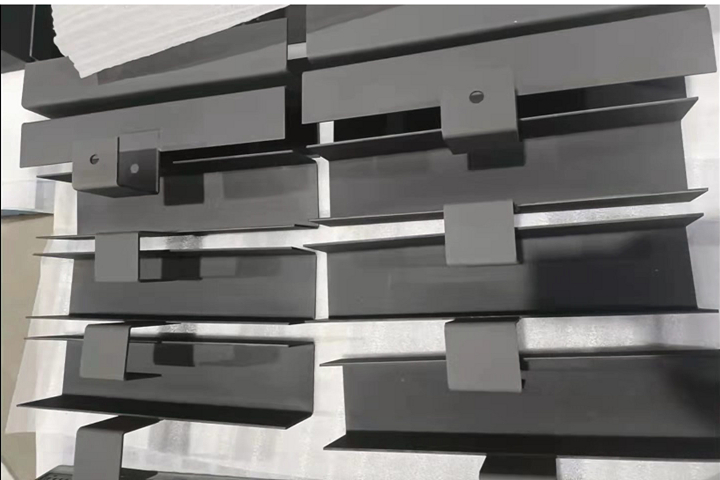

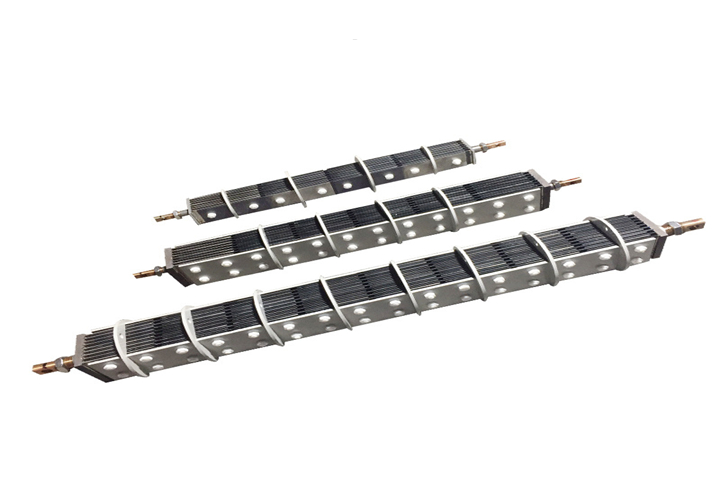

Substrate: Titanium Grade 1 Sheet

Coating: mixed Ruthenium-Iridium-Titanium oxide

Life span: 2-15years

Sodium hypochlorite generator is a diaphragm-less electrolysis method, which generates low-concentration sodium hypochlorite disinfection solution by electrolysis of low-concentration salt water, without the overload of by-products such as chlorate and chlorite of chemical method disinfection equipment.

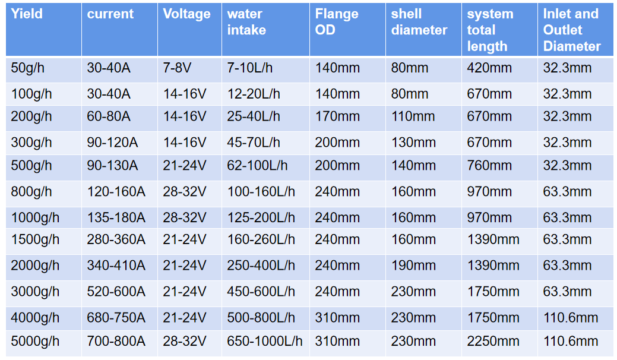

| Sodium Hypochlorite Generator Titanium Anode | |

| Working Parameter |

|

| Working Equipment | Sodium Hypochlorite Generator |

| Total reaction equation | NaCl+H₂O→NaClO+H₂↑ |

| Electrolyte | Saltwater / Saline solution/ Brine/ Seawater |

| Features |

|

Working details of sodium hypochlorite generator:

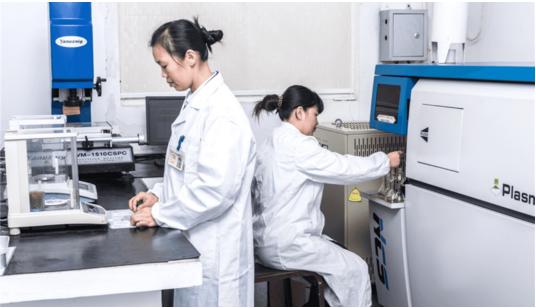

Quality checks:

Accelerated Life Test, Coating Thickness Test, Coating composition test, conduct electricity conductivity testing,

Surface roughness test, Helium Leak Detection Test, Contact Resistance Test, Electrochemical Performance Test, and other tests.

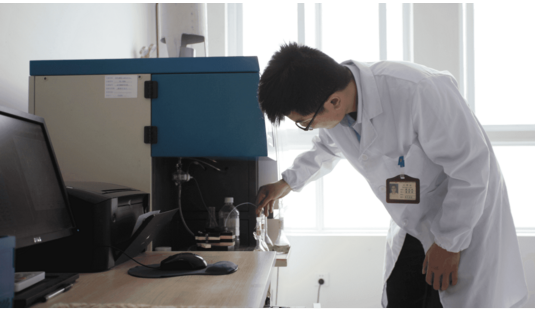

JOINTING R&D

Improving current efficiency and prolonging service life are the core technical indicators of DSA titanium electrodes. Different industries have different requirements for the performance of titanium electrodes. Even if the same industry uses the same system of electrocatalytic coatings for different electrolytes, it may not be possible. Bring the ideal use effect. Based on years of accumulated R&D and production experience and a high-level technical team, the company can tailor a coating system that meets its own production environment for target customers to meet the differentiated needs of different industries or different customers in the same industry.

Development of electrode materials for high chlorine evolution efficiency and long life. Development of electrode materials for high acidity and long-life oxygen evolution.

Development of new electrode materials for mixed acid systems.

Development of high-oxygen ultra-base metal electrode materials Development of electrode materials in special fields