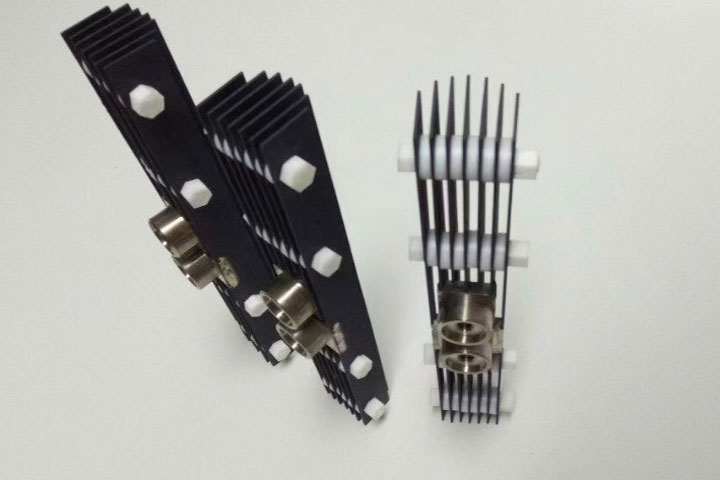

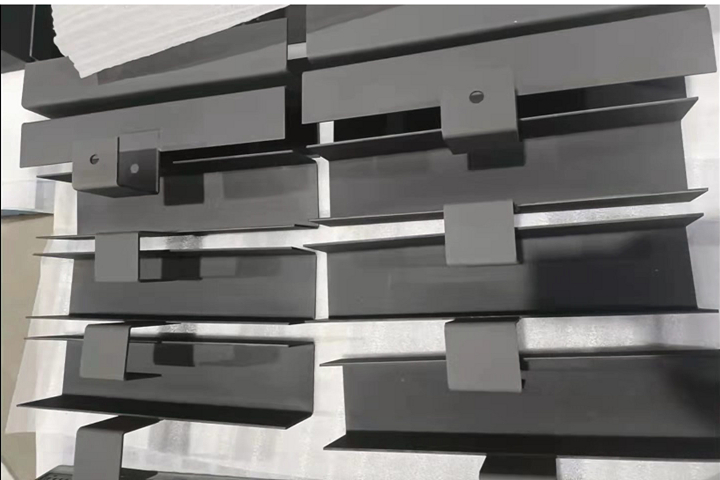

swimming pool water disinfection titanium anode

Substrate: Titanium Grade 1 Sheet

Coating: mixed Ruthenium-Iridium-Titanium oxide

Life span: 2-15years

ODEVS offers ruthenium/iridium coated DSA titanium anode for swimming pool water disinfection electrolytic chlorinator cells. The MMO coating of the titanium anode is optimized for maximum chlorine production, with excellent coating strength and adherence to the substrate for longer service life. The combination of industry-standard manufacturing of the titanium substrate and in-house MMO precursor materials fabrication enables ODEVS to provide the best competitive price of ownership.

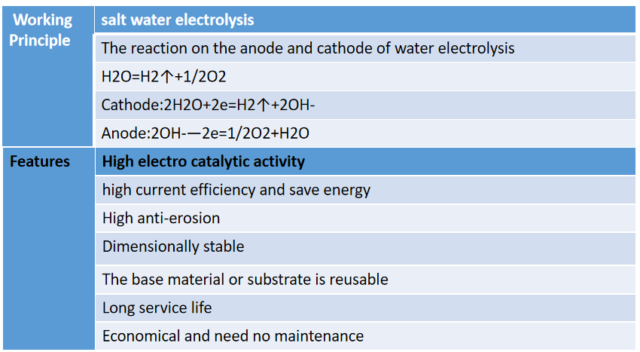

Working Parameter

Current range: 3A-7A

Current density: < 200A/M2(130A/M2=6/0.046m2)

Voltage range: 2V-18V

Working environment: Salt (sodium chloride) range of 3-4 g/L or seawater

Working temperature: 25-40 cent degrees

Chlorine-liberated potential: <=1.13V

Chlorine concentration: about 20g-40g/hour

Reversal Frequency: 2-3hours

There mustn’t be any fluorine and cyanide ions in the electrolyte

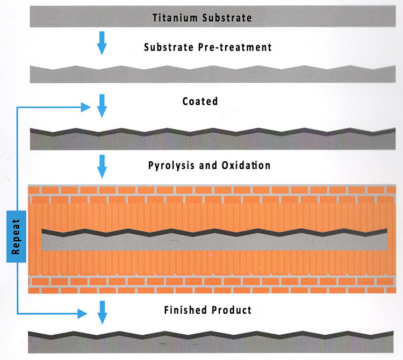

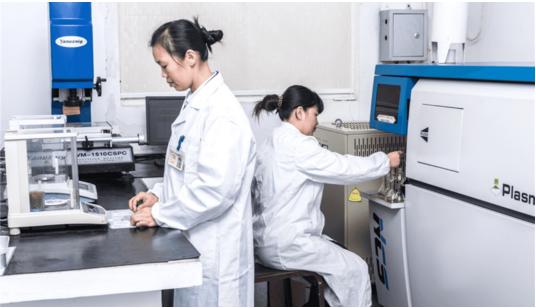

Processing Flow

Quality checks:

Accelerated Life Test, Coating Thickness Test, Coating composition test, Conduct electricity conductivity testing,

Surface roughness test, Helium Leak Detection Test, Contact Resistance Test, Electrochemical Performance Test, and other tests.

JOINTING R&D

Improving current efficiency and prolonging service life are the core technical indicators of DSA titanium electrodes. Different industries have different requirements for the performance of titanium electrodes. Even if the same industry uses the same system of electrocatalytic coatings for different electrolytes, it may not be possible. Bring the ideal use effect. Based on years of accumulated R&D and production experience and a high-level technical team, the company can tailor a coating system that meets its own production environment for target customers to meet the differentiated needs of different industries or different customers in the same industry.

Development of electrode materials for high chlorine evolution efficiency and long life. Development of electrode materials for high acidity and long-life oxygen evolution. Development of new electrode materials for mixed acid systems.

Development of high-oxygen ultra-base metal electrode materials Development of electrode materials in special fields