Cathodic Protection Titanium Anode

Substrate: Titanium Grade 1 strip

Coating: Iridium-tantalum/ruthenium-iridium

Coated Titanium Anodes for Impressed Current Cathodic Protection—MMO Active Coated Titanium Anodes use titanium as a substrate and use thermal decomposition to form an oxide coating of platinum group metals.

- Lightweight and good chemical stability, even in low pH and chloride ion-containing environments;

- During the design life of the anode, the size is stable;

- Uniform coating loss rate, 1-6mg/A.a;

- Can work under high current density, 2000A/m²;

- Conductivity, 10-7Ω·m.

Coating Type

| No. | Coating Type | Application |

| 1 | Ru-Ir-Ti |

|

| 2 | Ir-Ta |

|

Anode classification

- Wire anode

- Pure titanium wire: size and properties conform to ASTM standard B348 grade 1 and grade 2.

| Dia(mm) | Length(m) | Current output (mA/m) | Expected life(a) |

| 1.5 | 300 | 328 | 20 |

| 3.0 | 300 | 656 | 20 |

| Application |

|

||

2. MMO ribbon anode

substrate: Titanium strip conform ASTM standard B265 grade 1 and grade 2

Coating Type: IrO2-TaO5 -X

| Wmm | Tmm | Lmm | Current output (mA/m) | Expected life(a) |

| 6.35 | 0.635 | 152 | 17 | 75 |

| 12.7 | 0.635 | 152 | 34 | 75 |

|

Application and Features |

|

|||

3. Titanium conductor bar

Substrate: Titanium bar conform to ASTM standard B348 grade 1 and grade 2

Coating type: choose different types according to the medium used for cathodic protection

| Dia(mm) | Length(m) | Weight kg | surface area m² |

| 3.2 | 1000 | 0.036 | 0.01 |

| 6.4 | 1000 | 0.145 | 0.02 |

| 12.7 | 1000 | 0.57 | 0.04 |

| 19 | 1000 | 1.275 | 0.06 |

| Application and Features |

Condensate tank, heat exchanger, ground bed |

||

4. Mesh Anode

substrate: Titanium mesh conform to ASTM standard B265 grade 1 and grade 2

Coating type: choose different types according to the medium used for cathodic protection

| W mm | T mm | L mm | Weight g | surface area m² |

| 32.5 | 1 | 1220 | 178 | 0.08 |

| 20 | 1 | 1000 | 90 | 0.04 |

| Application and Features |

Can be made into a cylindrical shape to replace ferrosilicon anode Cathodic protection of reinforced concrete piers and bridge decks |

|||

5. Tubular Anode

Substrate: Titanium tube conforms to ASTM standard B338 grade 1 and grade 2

Coating type: choose different types according to the medium used for cathodic protection

| OD mm | T mm | L mm | W kg | surface area m² |

| 19 | 1 | 1200 | 0.3 | 0.072 |

| 25 | 1.5 | 500 | 0.25 | 0.039 |

| 25 | 1.5 | 1000 | 0.5 | 0.079 |

| 25 | 1.5 | 1200 | 0.6 | 0.094 |

| 25 | 1.5 | 1500 | 0.75 | 0.118 |

| 31 | 2 | 1200 | 1 | 0.121 |

| Application and Features |

|

|||

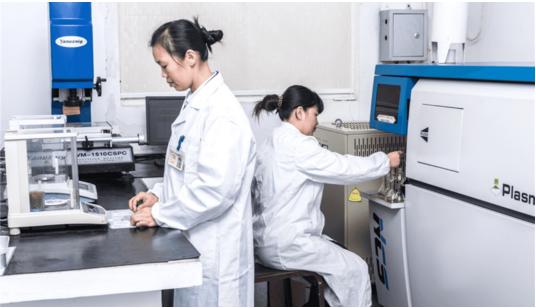

Quality checks:

Accelerated Life Test, Coating Thickness Test, Coating composition test, Conduct electricity conductivity testing,

Surface roughness test, Helium Leak Detection Test, Contact Resistance Test, Electrochemical Performance Test, and other tests.

JOINTING R&D

Improving current efficiency and prolonging service life are the core technical indicators of DSA titanium electrodes. Different industries have different requirements for the performance of titanium electrodes. Even if the same industry uses the same system of electrocatalytic coatings for different electrolytes, it may not be possible. Bring the ideal use effect. Based on years of accumulated R&D and production experience and a high-level technical team, the company can tailor a coating system that meets its own production environment for target customers to meet the differentiated needs of different industries or different customers in the same industry.

Development of electrode materials for high chlorine evolution efficiency and long life. Development of electrode materials for high acidity and long-life oxygen evolution. Development of new electrode materials for mixed acid systems.

Development of high-oxygen ultra-base metal electrode materials Development of electrode materials in special fields